- Whitepaper

A Technical Roadmap to Smart Manufacturing

Download Whitepaper

What's Inside This Smart Manufacturing Whitepaper?

This whitepaper on Smart Manufacturing explores how digital technologies are reshaping the manufacturing landscape. From AI and IoT to data-driven analytics, it covers the evolution of smart factories, their core benefits, and the technical building blocks.It also outlines a strategic roadmap for implementation, along with real-world case studies from leaders such as Siemens and Bosch. For manufacturers seeking to minimize downtime, enhance efficiency, and remain competitive, this guide provides actionable insights to align teams, systems, and objectives.

What is Smart Manufacturing?

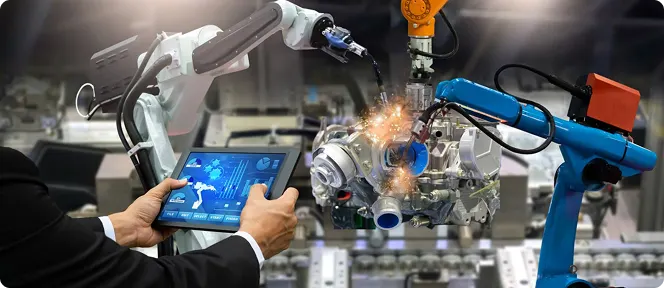

Smart manufacturing is a digital-first approach that connects machines, data, and people across the factory floor. It focuses on real-time monitoring, automation, and analytics to streamline operations, enhance quality, and expedite responsiveness to evolving production demands.

The Evolution of Smart Manufacturing

The journey from Industry 3.0 to 4.0 marks a shift from isolated automation to fully connected environments. Smart manufacturing leverages cloud platforms, sensors, and AI to continuously improve productivity, minimize waste, and drive enterprise-wide visibility and agility.

Key Benefits of Smart Manufacturing

Smart systems enhance decision-making and reduce inefficiencies. With real-time alerts, predictive models, and seamless device interactions, manufacturers can achieve better scheduling, optimized asset utilization, lower costs, and safer working environments—all while maintaining consistent product quality.

Core Technologies Enabling Smart Manufacturing

Smart factories rely on an integrated stack of technologies. These include IIoT sensors, 5G connectivity, AI and ML tools, digital twins, cloud-edge computing, robotics, and cyber-physical systems—all of which support dynamic, data-driven manufacturing processes.

Is Your Company Ready for Smart Manufacturing?

Before transforming, firms must assess their digital maturity, infrastructure, and readiness for change. This section helps evaluate strategic alignment, leadership support, workforce capability, compliance policies, and the scalability of current systems to support future smart operations.

Aezion's Strategic Roadmap to Implementation

Aezion supports manufacturers across the smart journey. From capability assessment and technology planning to pilot programs and change management, we deliver a step-by-step roadmap to help teams adopt smart systems aligned with business goals and measurable KPIs.

Challenges and Risks in Smart Manufacturing

Common obstacles include legacy system integration, high upfront costs, skill shortages, and unclear ROI. Addressing these requires disciplined planning, strong internal leadership, and expert guidance to manage disruption and build long-term operational resilience.

Case Studies and Real-World Examples

Global leaders like Siemens and Bosch showcase how predictive maintenance, IIoT, and automation drive efficiency and reduce downtime. These case studies demonstrate measurable benefits, including higher quality rates, lower operational costs, and smarter, data-aligned decision-making.

Key Takeaways

Smart manufacturing is no longer optional—it’s essential. With data engineering support, manufacturers can modernize their processes, align operations with strategy, and remain competitive in a connected global market. The time to make the transition is now.

Reasons to Read This Whitepaper

Get a Clear Overview of Smart Manufacturing

Discover how connected technologies and digital systems revolutionize manufacturing, from the shop floor to executive strategy.

Explore Core Technologies and Use Cases

Discover how AI, IIoT, digital twins, and 5G are applied across smart factories to increase agility and reduce risk.

Access a Readiness Checklist

Evaluate your company’s maturity and identify gaps in infrastructure, leadership, culture, and compliance.

Understand Aezion's Implementation Approach

Discover how Aezion enables manufacturers to create custom, scalable platforms that accelerate their smart manufacturing transformation.

Gain Practical Insights from Industry Leaders

Review case studies from Siemens, Bosch, and others to see real-world results from smart manufacturing adoption.

Stay Ahead of Industry Trends

Stay up-to-date with emerging concepts, such as predictive analytics, cyber-physical systems, and the workforce, that are reshaping manufacturing